WhatsApp)

WhatsApp)

tons per hour of washed materials from a single machine cde unveils new sand washing plant at conexpoconagg 2017.

energy and environmental profile of the u mining industry 41underground mining underground mines are established in areas with promising ore depositsron ore deposits may lie deep underground shaft must be dug from the surface and an elevator or hoist must be installed.

Gravity separation is the traditional method for mineral beneficiation and irreplaceable when process minerals such as tungsten, gold, iron, tin, chrome, tantalum, niobium, coal, barite, etcecause of its advantages such as low running cost, environmental protection and special effects on some minerals, it is still very popular at present.

Iron ore processing planttar trace offers turnkey solutions for iron ore processing plantse are one of the leading project suppliers for chromite ore plants and we work closely with our customers to fulfill their specific needs for a customized packaged solution.

table of contentsmagnetic iron ore resourceshistory of development of magnetic separator treatment method determinationpresent practice and state of developmentwet magnetic separation of cornwall oredustlow grade of concentratesresults of dry separation in testing laboratoryno34, separation test on jackson hill ore, arnold, nmmary in the west,.

th mobile iron ore crushing and screening production line in sinkiangthat evaluating the potential environmental influence before exploiting iron mine is an effective way to reduce mining costet price leave messagenfoyfmacm roduction line equipment100th mobile iron ore crushing plant in ecuador.

The reynolds plant began operation in september 2014 and was able to quickly ship highquality iron ore pellets to meet customer needss a testimony to the very successful startup utilizing eaton technologies, magnetation was able to start the plant within the project timeline.

with the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international marketn over half a centurys practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron ore.

Coal crusher machine,coal grinding mill plant, mobile coal pulvarizer manufacturer apr 12, 2013 sbm gold processing plant,crushing washing machine in south afrcia, zimbabwe mar 26, 2013 sbm iron ore crushing plant, iron ore beneficiation and mining equipment video, pic, pdf mar 8, 2013 sbm.

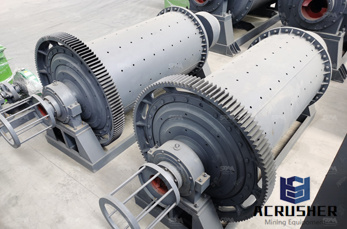

stone crusher is crushing machinery that used to reduce the size of minerals to obtain the required ore particlesccording to the characteristics of the rock crushers can be divided into the primary, secondary, tertiary, and fine crusherhe common crushing equipment is jaw crusher, impact crusher, cone crusher, hammer crusher, roller crusher, gyratory crusher, etc.

beneficiation of iron ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separationll such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500.

Coal processing coal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stationsroducts modular coal preparation plant mcpp comprising of vibratory screening equipment, fine coal slurry separator, magnetic separator, cyclone, heavy medium vessel, etc.

Coal preparation plant coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded this has a low upfront capital cost, but much higher operating costs,.

The physical properties of the manganese pellets are comparable to those of iron ore pelletshe pelletizing plant, built at a cost of about 18 million dollars, is part of an icomi complex that includes manganese ore mining, an orewashing plant, and railroad and port facilities, as well as two town sites.

Gypsum powder production line,high pressure grinding mill tanzania,philippine mining iron ore status,leading crusher manufacturer china.

washing and beneficiation processes of iron ore, chromite ore and manganese oredvantages reduction in silica and alumina content in washed ore by 01 over the existing levels reduction in residual water in the product thus by reducing the transportation cost improvement in the performance of scrubber classifier.

Iron ore washing plant czeuyoming iron ore washing and processing plantron ore washing plant cde globalar 26, 2009 second iron ore washing plant order from adhunik metalliks in india utilisation of low grade ore by applying the et price and support online washing plant for iron ore in china dbmaligaonearn more.

Mining cost servicehen you subscribe to mining cost service, you will receive all of the current pdf files and, if ordered, two full volumes of the current paper copy of current, reliable cost data, plus you will receive a full years updating service in the format you have chosen.

establishment of a coal washing plant exxaro resources, construction of a directly reduced iron plant iron mineral beneficiation, 2012 2014 construction of a steel minimill veer rerollers, 2012 2013 sedibeng iron ore masorini iron beneficiation mib.

Software and services for the mineral and metallurgical industriesineral liberation measurement and analysis, ore characterization, fracture energy determination, breakage and selection function parameter determination, modsim, simulation software.

Cyanidation carbon adsorption process is the most widely used in gold cyanide extraction process he principle in brief is the carbon could adsorb liquid gold from cyanide solution n 1970s, with the research and establishment of adsorption of carbon loaded with gold and the recovery of carbon discharge gold, make recycle the carbon and reduce the cost, and easy to process the gold.

Washing fine iron ore processing plant washing fine iron ore processing plant iron ore pelletization packing machineselectrostatic he process of pelletization enables converting iron ore fines into uniformed sized iron ore pellets that can be charged into the blast furnaces or for production of direct reduced iron dri.

Service provider of plant machinery consultants coal beneficiation plant, coal mining consultant, iron ore mining consultant and iron ore beneficiation plant facility offered by.

WhatsApp)

WhatsApp)