WhatsApp)

WhatsApp)

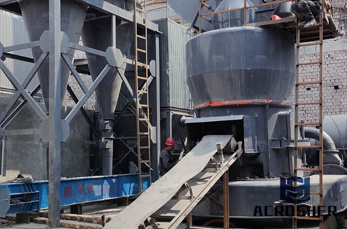

Vertical Raw Mill Great Wall. Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particlVertical roller mills are ...

Vertical Roller Mill Shanghai Oriental Heavy Industry machinery Co vertical raw mill process control,Vertical Roller Mill is mainly applied in the grinding ...

Optimization of Vertical Raw Mill Operation Free download as PDF File (.pdf), Text File (.txt) or read online for free.

Kiln and Raw Mill 33 3 3kV New A Sub Station prices ... vertical shaft kiln cement ... burners for high temperature shaft kiln; cement process dry technology ...

Your Location: Home >> Quarry Process Solution >>mass balance grinding mill. Stone Crusher Quarry Crusher jaw crusher ... heat mass balance for vertical raw mill ...

starting process of vertical raw mill in cement plant pdf. Simply complete the form below, click submit, you will get the price list and a GBM representative will ...

Copper is one of the basic chemical elements. In its nearly pure state, copper is a reddishorange metal known for its high thermal and electrical

FLATOX Vertical Raw Mill grinds all types of raw. The ATOX Raw Mill is a highly efficient mill that grinds all types of rawReliable operation/high uptime; High ...

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely used in the concrete and ...

Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building ...

Raw Meal Grinding Vertical Mill Fundamentals. GICCement Process > Cement Manufacturing Process. The dosed raw materials are dried and finely ground in the Raw Mill .

vertical raw mill and cement mill operation. vertical raw mill system design considerations m 10th raw mill system design considerations material grindability type of ...

Nov 16, 2011· Process in vertical raw mill ... This feature is not available right now. Please try again later.

Home > Mill > working of vertical raw mill in cement plant. ... Our 3000 ton dry process cement plant comes with four silos in the raw material batching station for ...

Cenin Cement Manufacturing. All raw materials including clinkers are processed by a vertical roller mill or ball mill. The milled raw materials go through a quality ...

Raw Mill In Cement Plant; ... This is achieved in a cement raw mill. The grinding process is controlled to obtain a powder with a broad ... Vertical Roller Mill ...

Feb 26, 2013· Video embedded· This film demonstrates all aspects of the FLSmidth ATOX® raw mill: how it saves space and energy and why it has been proven to deliver reliable operation ...

loesche raw mill. Madras Cement will ... Process in vertical raw mill ... Working of loesche Mill: Raw material comes into raw mill from ...

Vertical roller mills are widely accepted ... process – regardless of variations in ... Therefore the ATOX raw mill is

The ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials – saving both space and energy while delivering outstanding performance

Cement grinding Vertical roller mills versus ball mills ... 80 years it was the predominant mill for grinding of raw ... vertical roller mill takes place by exposing ...

cement vertical raw mill design Optimization of Vertical Raw Mill roller mill designs for through put rates of x raw materials for the cement ...

Advanced Process Control Toolkit for Cement Gensym vertical raw mill process control,, or Cement Advanced process control Toolkit, provides advanced process ...

Vertical roller mills are widely accepted ... The grinding table of the ATOX raw mill has a flat, horizontal grinding track ... Optimised separation process

WhatsApp)

WhatsApp)