WhatsApp)

WhatsApp)

wet grinding and dry grinding; ... New Type Dry Process Cement Production LineThis new type dry process cement production line is a kind of cement production ...

Cement manufacturing process, cement production process, Two Manufacturing Processes Two different processes, "dry" and "wet," are used in the manufacture of ...

Portland Cement Manufacturing ... and finished cement grinding. Each of these process components is ... Dry process pyroprocessing systems have been improved in ...

Key words: dry grinding, process optimisation, modelling INTRODUCTION ... be applied in cement grinding optimisation. Only the cement clinker grinding is discussed

Global Cement online portal for all things cement related

Stucco Frequently Asked Questions (Stucco FAQs) ... Now that we are seeing cold weather, are there any restrictions on plastering at lower temperatures?

Feb 15, 2017· More Details : dry and wet process of cement manufacturing Grinding Mill ... 201289dry and wet process of ...

A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill);

Early rotary cement kilns in Britain ... A second kiln was installed at Barnstone. Francis suggests that Ransome chose "a remote locality" to avoid undue ...

heating the rawmix to sintering temperature (up to 1450 °C) in a cement kiln; grinding the resulting clinker to make cement ... In the dry process, ...

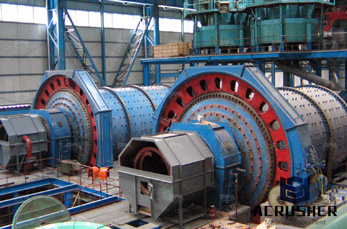

A wide selection of BALL MILLS available. Call us for more details.

Union Process offers a full line of high quality grinding media balls, engineered to meet your most demanding milling applications.

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and nonspecialty grout.

Executive Summary Cement, Lime and Magnesium Oxide Manufacturing Industries iii of energy. The secondary processes of lime slaking and grinding can also be of ...

The Largest Paving Contractors in Buffalo, NY. We do Asphalt Paving, Concrete, Drain Work, Seal Coating, Line Striping, Crack Filler Site Work. Contact Us!

Lucky Cement Limited (LCL) is one of the largest producers and leading exporters of quality cement in Pakistan, with a production capacity of million tons.

Size Reduction and Grinding ... The Rosin Rammler Distribution (RRD) is applicable to materials that have been ground by a process that breaks uniform brittle ...

Figure 2: The integrated cement plants and standalone cement grinding plants in the UAE in 2014, colourcoded by installed integrated cement production capacity in ...

People often ask us if stucco, or portland cement plaster, will adhere to concrete or concrete masonry.

Dry Process Cement Grinding Vertical Roller Mill For Sale, ... has the characteristics of high efficiency in powder milling, low power consumption, ...

In the cement pyroprocessing process it is important to keep in mind that waste materials combust and burn at different temperatures under different conditions.

People sometimes ask me if I can recommend a good dry cat food, but I cannot. Dry food — kibble — is the worst possible food you can feed to your cat.

WhatsApp)

WhatsApp)