WhatsApp)

WhatsApp)

How cement is made and history of Portland Cement. ... CEMENT MANUFACTURING CAPACITY, ... a process that saves .

Cement Manufacturing Process. Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix.

Manufacture process of cement, Making of cement, all making process of cement from start to the end of packing of cement.

patented jan. 10, 1933 united states patent" office, james h. colton, of berkeley, california, assignor to pacific portland cement company, consolidated, a ...

Mar 29, 2012· Lucky Cement Limited (LCL) is Pakistan''s largest producer and leading exporter of quality cement with .

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silica ...

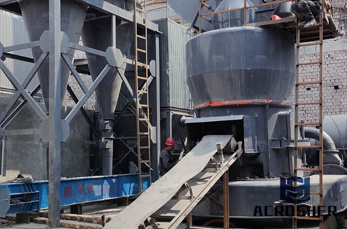

THE PROCESS Manufacturing Skyway Cement requires two basic processes, granulation and grinding. Granulation This process transforms molten slag into granules.

Cement Manufacturing Process Raw Materials The hydraulic property of cement originates from its cement minerals ( calciumsilicates). The major co...

manufacturing of cement. ... (to control the time of set of the cement). ... Wet process. cement. Share. Share. Facebook Twitter Google+ LinkedIn Email.

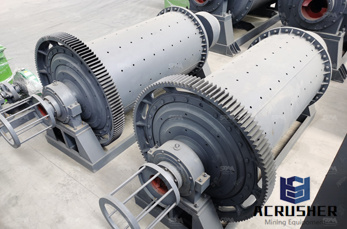

Portland Cement . Cement: ... Methods of cement manufacturing 1 Wet process ___ grinding and mixing of the raw materials in the existence of water.

Water plus cement plus aggregates. The formula seems simple, but the reality of concrete manufacturing is far more complex. The development of...

–Cement Manufacturing Process– The raw materials needed to produce cement (calcium carbonate, silica, alumina, and iron ore) are generally extracted from ...

Thanks for the A2A. Even though cement is a major component of most of my projects, I never really thought about how cement was manufactured. Your question i...

Manufacturing process < All about Cement < Cement : Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement ...

Alternative Raw Materials and Fuels Process. Lafarge is a leader in the use of alternative raw materials and fuels for fueling manufacturing operations. Lafarge''s tirederivedfuel and plasticderivedfuel processes use scrap tires and nonrecyclable plastics, as complements to coal, for fueling its cement plants.

Cement manufacturing process components of a cement plant from quarry to kiln to cement mill.

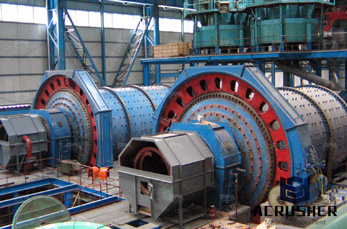

Video embedded· Cement Manufacturing Process. The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain uniform quality of cement .

Cement manufacturing is truly a oneofakind business. It requires a spectrum of technology found in few industries. The 24/7 continuous process of chemical and ...

From the limestone quarry till the delivery of the final product, the following steps describe the cement manufacturing process: 1. Extraction of Raw Materials The ...

Portland Cement Manufacturing; Basic Information; ... Portland cement manufacturing is an energyintensive process that grinds and heats a mixture of .

Cement manufacturing is not as complex as it seems to be. To make cement, industrial plants follow step by step systematic process. Here .

In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill.

Jul 31, 2013· Video embedded· JK Lakshmi Cement Manufacturing Process Duration: 4:12. ... Manufacturing of Cement| part 5 Duration: 8:44. Wahthu Elearning 21,271 views. 8:44.

Different minerals need to be mined in order to make cement. Limestone (containing the mineral calcite), clay, and gypsum make up most of it. The US Geological Survey ...

WhatsApp)

WhatsApp)