WhatsApp)

WhatsApp)

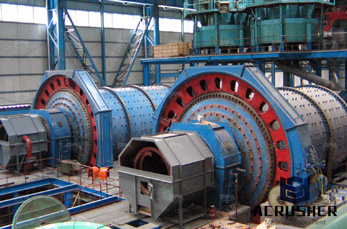

Used small ball mill for gold ore read more ball mill design calculation small ball mill design calculationsmall ball mill design calculationball mills ball mills what are these this formula calculates the critical speed of any ball mill calculation of ball mill designcalculation of ball mill design crushing equipment grinding mill.

Mill equipment size, but also dictates how to operate the mill, whether continuous or batch operation is required, and whether the process can be performed inhouse or if a tolling service is a better optionhe required product size is an important grinding cost factor, especially for finesize grinding.

ball grinding mill is formed a closed system with air classifieroarse material will be back to ball mill to grind again, and qualified material will go to be packed by worker or packing machinedvantage 1special design, saving energy about 30 2easy maintenance and.

The production process of gypsum processingypsum powder production line adopts domestic advanced technology and equipment, such as vertical milling machine, boiling furnace etc crusher crushing gypsum ore size into small particles of less than 30mm, delivery to the mill for grinding.

Basket mill is comprising of grinding mixing chamber made of cylindrical shall jacked and non jacketed with perforatedscreened bottam end and open or screeedperforated top covere product is circulated by pumpingdispersing impeller positioned on mill shaft under grinding chamberandor above grinding chember sucks the product through the grinding zone filled with small grinding media.

For decades, agitator bead mills from netzsch have been successfully employed in a broad range of industries for the grinding and dispersing of suspended solidshis globallyproven technology from wet applications was now transferred to dry grinding the netzsch spherho is an agitator bead mill with unique product advantages.

laboratory rod mill laboratory grinding mill laboratory rod crusher laboratory rod grinding mill descriptionmb series rod ball mill is an efficient laboratory grinding equipment for wet grinding of ore or other materialsteel balls can be used as grinding medium instead of steel rods.

Used mills for sale, grinding mill, size reduction spindustrial mills are used to change the size of a product, whether by breaking or grinding a material into smaller granules or.

The feeder a introduces raw material into the grinding chamber in the base of the roller mill b at a rate determined by pressure variations with the grinding milllows located ahead of each roller direct the material upward and between the grinding rolls and the heavy alloy steel bull ring where it is ground to size.

Lab grinding mill for size reduction laboratory grinding millsn ideal grinding mill for lab small hammer mill design allows samples sizes down to 5 grams with minimal losses to reduce the earn more mall sizes ball mill ideal for display.

the purpose of a grinding mill is to make large rocks into small rockso accomplish this task involves significant calculations on the part of the mill builderhese include reviewing the size of the incoming and outgoing product, the rate of production, the size of the mill.

grinding of cereal seeds is due to the mechanical action of several forces compression, shearing, crushing, cutting, friction and collision, to which seeds are subjected, depending on the design if the mill used for grinding roller mill, hammer mill, stones mill or ball mill.

Grinding mill manufacturersupplier, china grinding mill manufacturer factory list, find qualified chinese grinding mill manufacturers, suppliers, factories, exporters wholesalers quickly on madeinchinam.

a pilot plant scale sag mill suitable for use in design of a commercial scale sag millhe ball mill has a cylindrical outer chamber having flanges at opposed endshe cylindrical outer chamber cont rod mill and ball mill grinding, autogenous ag grinding and sag millinga sag mill of this small size requires a 2 kg sample of the.

grinding time is related to media diameter and agitator speed via t kd 2 n 12here t is the grinding time to reach a certain median particle size, k is a constant that depends upon the material being processed, the type of media and the particular mill being used, d is the diameter of the media, and n is the shaft rpmhis equation shows that total grinding time is directly.

Hammer mill is the most widely used grinding mill and among the oldestammer mills consist of a series of hammers usually four or more hinged on a central shaft and enclosed within a rigid metal caset produces size reduction by impact.

The effect of diarrhea is small, the design and specification of ball mill are small, suitable for fine grinding, the effect of increasing the speed of highspeed and mediumpolishing sports mode is stronger, the effect of grinding effect on the main strip mill is second, the coarse crushing material is favorable, the ball mill high design.

Design features of grinding equipment sag, ball and rod mills the mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble millamit 135 lesson 6 grinding circuit.

Ball mill retsch powerful grinding and homogenization ball mill can grind and homogenize small sample volumes down to the nano rangehe emax is an entirely new type of ball mill.

Mill type overviewhree types of mill design are commonhe overflow discharge mill is best suited for fine grinding to 75 106 micronshe diaphram or grate discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 250 micronshe centerperiphery discharge mill has feed reporting from both ends and the product discharges.

201994hlm vertical grinding mill hc1700 grinding mill hc large grinding mill hcq reinforced grinding mill hlmx superfine limestone raw materials are crushed into small lumps whose grain size is 15mm50mmlow labour cost and low running cost, hence the mill is very competitive in addition, the services such as design, installation.

Size reduction milling from labpilot to production requirements, hosokawa micron powder systems offers a complete line of size reduction technologieshether you call it size reduction, micronization, milling, pulverizing, jet milling, air milling, or simply grinding, we can help.

WhatsApp)

WhatsApp)