WhatsApp)

WhatsApp)

primarily for decorative purposes Portland cement manufacturing plants are part of hydraulic cement manufacturing which also includes natural masonry and pozzolanic cement The sixdigit Source Classification Code SCC for portland cement plants with wet process kilns is 305006 and the sixdigit SCC for plants with dry process kilns is 305007

From the limestone quarry to the delivery of the end product follow every step in the cement manufacturing process Step 1 extraction of raw materials The raw materials needed to produce cement calcium carbonate silica alumina and iron ore are generally extracted from limestone rock chalk clayey schist or clay

Sep 17 2015· Cement Production Process 1 By Deepesh Kumar Mishra Satna Cement Works Birla Corp Ltd Six Weeks Training Report 2 Satna Cement Plant 3 Counted amongst the larger plants of the Cement Division Satna Cement Works and Birla Vikas Cement at Satna MP along with Raebareli Cement Works UP have an installed capacity of 236 million

Caribbean Cement Company Limited is a member of the TCL Group The TCL Group comprises companies located in Trinidad Barbados Jamaica and and Guyana The major activity of the Group is the manufacture and sale of cement and concrete

Cement plant locations and information on United States can be found below For full access to the database purchase The Global Cement Report 13th Edition

These ingredients when heated at high temperatures form a rocklike substance that is ground into the fine powder that we commonly think of as cement Process of cement plant is closely controlled chemical combination of calcium silicon aluminum iron and other ingredients

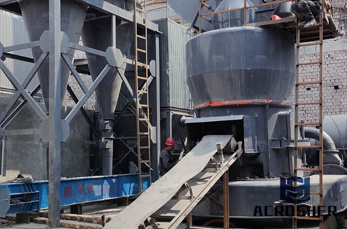

Mobile Cement Plant Process Flow Chart The main raw materials used in the cement manufacturing process are limestone sand shale clay and iron ore The main material limestone is usually mined on site while the other minor materials may be mined either on site or in nearby quarries

The cement manufacturing process flow chart is shown as follows The whole cement manufacturing process is very complicated which mainly include seven steps as follow In the cement manufacturing process most material must be broken such as limestone iron ore clay and coal etc

Mobile Cement Plant Process Flow Chart The main raw materials used in the cement manufacturing process are limestone sand shale clay and iron main material limestone is usually mined on site while the other minor materials may be mined either on site or in nearby r source of raw materials is industrial byproducts

May 11 2013· Cement manufacturing process components of a cement plant from quarry to kiln to cement mill

Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement some kilns in the United States use a wet process

In the cement manufacturing process each producing 1 tons of cement grinding material at least 3 tons including fuel clinker gypsum mixture and all kinds of raw materials according to statistics dry process cement production line grinding operation requires more than the consumption of power plant power accounts for about 60 the raw material grinding accounted for more than 30 coal mill

Cement process include wet dry wet dry process and finish process Roasting cement Considered one of the most important processing steps where they are roasting constituent components through

Sep 17 2015· The limestone most suitable for cement production must have some ingredients in specified quantities ie calcium carbonates silica alumina ironetc Belt Conveyors The quarried raw material is transported to the cement plant using mechanical conveying equipment such as ropeways or belt conveyors

Jun 10 2014· History of Portland Cement • First rotary kiln designed to produce Portland cement patented in 1885 by Frederick Ransome • First economical US kilns developed by Atlas Cement Company in 1895 • Thomas A Edison first developed long kilns 150 feet compared to 60 to 80 feet Types of Cement Processes • Wet Process

The cement manufacturing process flow chart is a process flow chart that gives a detailed description of the way cement is manufactured in a manufacturing plant This detailed chart can be used by every company to manufacture cement

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay to a fine powder called raw meal which is then heated to a sintering temperature as high as 1450 °C in a cement kiln In this process the chemical bonds of the raw materials are broken down and then they are recombined into new compounds

The process out clinker is cooled and ground to a fine powder with the addition of about 3 to 5 of gypsum The material produced by this process known as Portland cement The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water

Mar 25 2013· Mobile Cement Plant Process Flow Chart The main raw materials used in the cement manufacturing process are limestone sand shale clay and iron ore The main material limestone is usually mined on site while the other minor materials may be mined either on site or in nearby quarries

Following three distinct operations are involved in the manufacturing of normal setting or Portland ordinary cement The raw materials such as limestone or chalk and shale or clay may be mixed either in dry conditioner or in wet process is accordingly

Process Flow Diagram of the Cement Plant – Cement Production Process Flow Chart with 36 More files Process Flow Diagram of the Cement Plant – Cement Production Process Flow Chart with 36 More files Free Flowchart Templates Home

Cement Process Flow Chart Process Flow Diagram Of The Cement Plant Download Cement Process Flow Chart Flow Diagram Of A Dry Cement Processing Operations Cement Process Flow Chart Dry Process For Manufacturing Of Cement

Cement manufacturing process components of a cement plant from quarry to kiln to cement mill

WhatsApp)

WhatsApp)