WhatsApp)

WhatsApp)

Iron Ore mining investment and price news from The latest news on iron ore mines and properties mining companies and iron ore prices

Beneficiation of Iron Ore and the treatment of magnetic iron taconites stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50000 tons per day and ultimately requiring grinding as fine as minus 500

Iron Ore Processing Working with Iron Ore industry to improve recovery Products Train Loading System Vibrating screen Vibrating feeder etc Schenck Process has been an international expert at iron ore processing

Nov 21 2014· The iron ore that is blasted is stacked and loaded upon large dumpers to be moved to the blast furnaces for smelting process Benches are made for the process of iron ore mining Mechanized mining involves creation of benches that are used for the purpose of drilling blasting and finally the transportation of the iron ore to the crushing plant

The Iron Ore Mining industry has benefited from rising prices and higher production volumes over the past five years As a result industry revenue is expected to increase at an annualised 11 over the five years through 201920 to 812 billion This trend includes an anticipated 26 fall in the current year due to a decline in iron ore prices

The smelting process allows the iron ore to be heated with carbon The carbon combines with the oxygen and carries it away leaving behind iron Blast furnaces are so hot which is why they melt the iron and drain it off to be poured into moulds to form bars called ingots

Iron processing use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting

The iron ore production has significantly expanded in recent years owing to increasing steel demands in developing countries However the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking

The iron ore pelletizing process consists of three main steps 1 Pelletizing feed preparation and mixing the raw material iron ore concentrate additives anthracite dolomite and binders are prepared in terms of particle size and chemical specifications dosed and mixed together to feed the pelletizing process 2

Operations overview Roy Hill is a 55 million tonne per annum Mtpa iron ore mining rail and port operation in West Australia''s Pilbara region

Sep 17 2015· China is the leader in both steel production 50 of world total and iron ore mining 47 of global output in terms of tonnage China is also the biggest iron ore importer and as of April 2015 consumed more than 80 of the 13 billion tonne seaborne trade Steel consumption in

The steelmaking process starts with the processing of iron ore The rock containing iron ore is ground and the ore is extracted using magnetic rollers Finegrained iron ore is processed into coarsegrained clumps for use in the blast furnace Coal is cleaned of impurities in a coke furnace yielding an almost pure form of carbon A mixture of iron ore and coal is then heated in a blast furnace to produce molten iron or

The unpredictability and volatility of global markets like iron ore can make or break a mining company in a matter of weeks Sudden drops in the price of iron ore can wipe billions of dollars worth of profit from mining operations

Most iron ore leaves the mine by rail after which much is transferred to ships A much larger proportion of ore is moved by water in the United States than elsewhere because of the proximity

The deep mining of iron ore is unusual in the modern era but in northern Sweden ore is mined from considerable depth largely aided by the application of automation and remote control equipment Kiruna has been chosen as the example for a more detailed review of underground techniques

Ferrexpo produces iron ore pellets with a majority 65 iron grade and a small minority with 62 iron grade We possess the technical skills required to beneficiate and process iron ore into iron ore pellets The diagrams below provide an overview of the production process 1 Ore from mine Open cut hard rock iron ore mining using truck and shovel

Sep 17 2015· Vale''s Carajas Mine Complex is the second biggest iron ore production center which consists of three openpit mines namely Carajas N4E N4W and N5 and operated as the Serra Norte Mining

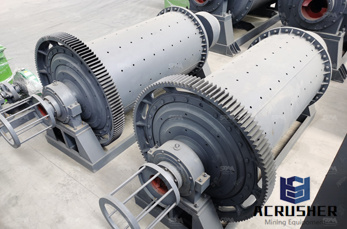

Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse

Ore a natural aggregation of one or more minerals that can be mined processed and sold at a profit An older definition restricted usage of the word ore to metallic mineral deposits but the term has expanded in some instances to include nonmetallics

Jan 20 2017· Mining iron ore begins at ground level Taconite is identified by diamond drilling core samples on a grid hundreds of feet into the earth Taconite rock comprises about 28 percent iron the rest is sand or silica These samples are analyzed and categorized so that mining engineers can accurately develop a mine plan

Iron Mining Process From blasting to crushing to separation – more than 85 of the iron mined in the United States is mined in northeastern Minnesota to make our nation''s steel Blasting

Mar 14 2014· The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent location and value of the ore body

WhatsApp)

WhatsApp)