WhatsApp)

WhatsApp)

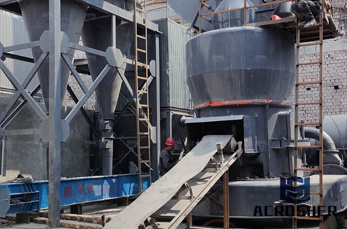

The Manufacturing Process Trinidad Cement Limited. TCL uses what is known in the industry as a wet process technology for the manufacture of cement.

Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two.

Wet Process for Manufacturing of Cement The raw material used in wet process is soft in nature. The climate is fairly damp and fuel is cheap. They are mixed in

Untitled . efficiency and water conservation for Wet Process Cement Manufacturing, with Reuse of CKD landfill leachate for CKD landfill dustsupressant and process

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of

taken in the wet process of cement manufacturing, burn ing operation has the highest consumption of the total energy required for manufacturing, ranging from % .

How cement is made and history of Portland Cement. Skip To The Main Content. Economics. Apparent ... The two processes are essentially alike except in the wet process

The wet process of cement manufacturing involves adding water to finely crushed raw material, such as line, clay or iron ore, in a proportion of 35 to 50.

· Wet process. Dry process. Now let ... Cement Manufacturing Process Duration: 2:22. ... Introduction of cement in Hindi |Manufacturing of Cement ...

Cement manufacturing process | CEMBUREAU. What is cement? Cement is a fine powder which sets after a few hours when mixed with water, and then hardens in a few .

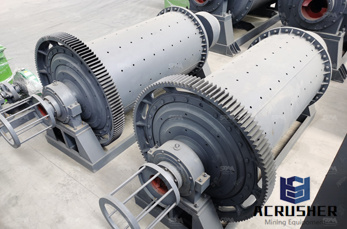

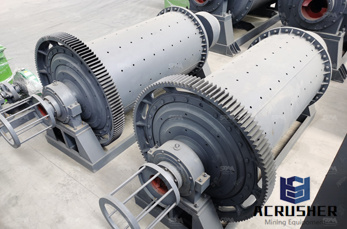

dry and wet process of cement manufacturing. Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry.

Cement manufacturing process 1. is cement ? of Cement Manufacturing process. of Kiln process. burn wastes ?

Wet Process Cement Manufacturing, Wholesale Various High Quality Wet Process Cement Manufacturing Products from Global Wet Process Cement Manufacturing .

Wet Process Of Cement Manufacturing, Wholesale Various High Quality Wet Process Of Cement Manufacturing Products from Global Wet Process Of Cement Manufacturing ...

In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill.

The Manufacturing Process – Trinidad Cement Limited. TCL uses what is known in the industry as a wet process technology for the manufacture of cement.

Portland Cement . Cement: is a ... Methods of cement manufacturing 1 Wet process ___ grinding and mixing of the raw materials in the ... Wet process When chalk is ...

Superior Bond. Fast Setting. SPEC MIX® Wet Process Shotcrete is a preblended pneumatically applied concrete designed for wet process repair applications ...

Process of cement making plant: 1. Raw Materials The main raw materials used in the cement manufacturing process are limestone, sand, shale, clay, and iron ore.

manufacturing of cement. in cement: ... The three processes of manufacture are known as the wet, dry, ... Wet process. cement. Share.

manufacture of cement by wet process. ... The wet process of cement manufacturing involves adding water to finely crushed raw material, such as limestone, ...

cement manufacturing wet process ppt India from XSM. Shanghai XSM (cement manufacturing wet process ppt India) is professional manufacturer, the main .

In wet process if chalk is used, it is finely broken up and dispersed it in water in a wash mill. Wash mill is a circular pit consisting of revolving radial arms ...

A cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used solely, but is ...

WhatsApp)

WhatsApp)