WhatsApp)

WhatsApp)

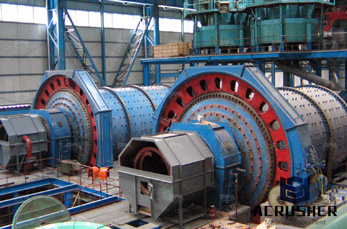

There are four stages in the manufacture of portland cement 1 crushing and grinding the raw materials 2 blending the materials in the correct proportions 3 burning the prepared mix in a kiln and 4 grinding the burned product known as "clinker" together with some 5 percent of gypsum to control the time of set of the cement

The kiln has to operate continuously in order to ensure a steady regime and therefore uniformity of clinker The larger existing kiln in a wet process plant produces 3600 tonnes of clinker per day The manufacture of cement by wet process is energy intensive and thus uneconomical as compared to dry process and semi dry process

The manufacturing process of Ordinary Portland cement is made primarily from calcareous and argillaceous materials such as limestone or chalk and from aluminium oxide silica oxide ferric oxide and magnesium oxide found as clay or shale

Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden Cement is manufactured through a closely controlled chemical combination of calcium silicon aluminum iron and other ingredients Common materials used to manufacture cement include limestone shells

Jul 31 2016· This slide explains step by step process of manufacturing of portland cement Slideshare uses cookies to improve functionality and performance and to provide you with relevant advertising If you continue browsing the site you agree to the use of cookies on this website

What Are the Differences Between the Wet and Dry Processes of a Cement Manufacturer The wet process of cement manufacturing involves adding water to finely crushed raw material such as limestone clay or iron ore in a proportion of 35 to 50 percent water to 50 to 65 percent raw material to make a slurry that is fed into a cement kiln whereas no water is added in the dry process

In dry process for manufacturing of cement the raw materials are dried and reduced in size to a fine powder in to grinding mill The dry powder is called the raw meal The raw meal is pumped into a blending silo The raw meal is blended by passin

manufacturing of cement In cement Manufacture of cement are known as the wet dry and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry ground dry and fed as a dry powder or ground dry and then moistened to

Jun 10 2014· Portland Cement A hydraulic cement made by finely powderising the clinker produced by calcining to incipient fusion a mixture of argillaceous and calcareous materials Portland cement is a powder that is the active ingredient in concrete 3

Jul 31 2016· Manufacturing of portland cement 1 Manufacturing of portland cement 2 CEMENT • A powdery substance made by calcining lime and clay mixed with water to form mortar or mixed with sand gravel and water to make concrete

Cement manufacturing process what is cement made of it can be discussed conveniently under two headings Selection of Raw materials and manufacturing methods Raw Materials of Cement Most important raw materials what is cement made of required in the manufacture of Portland Cement are Limestone Clay Gypsum Fuel and Water in wet method

The Process for Making Portland Cement Materials that contain appropriate amounts of calcium compounds silica alumina and iron oxide are crushed and screened and placed in a rotating cement kiln Ingredients used in this process are typically materials such as limestone sandstone marl shale iron clay and fly ash

The thermal efficiency of the wet process is much lower than the dry process the wet process has been almost universally replaced by dry or semidry process The wet process of cement manufacturing differs from the dry process only in that the materials are ground and burned wet No drying of raw materials is necessary

Portland cement manufacturing plants are part of hydraulic cement manufacturing which also includes natural masonry and pozzolanic cement The sixdigit Source Classification Code SCC for portland cement plants with wet process kilns is 305006 and the sixdigit SCC for plants with dry process kilns is 305007

Portland cement the only type of cement in common use today is manufactured in a four step process Step 1 Quarrying Limestone and a cement rock such as

Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden Cement is manufactured through a closely controlled chemical combination of calcium silicon aluminum iron and other ingredients The most common way to manufacture Portland cement is

May 22 2013· There 2 main process that can be used in manufacturing of Portland Cement that is i wet process ii dry process Wet Process Raw materials are homogenized by crushing grinding and blending so that approximately 80 of the raw material pass a No200 sieve The mix will be turned into form of slurry by adding 30 – 40 of water

Portland cement is b y far the most common type of cement in general use around the world This This cement is made by heating limestone calcium carbonate with other materials such as cla y to

Aug 30 2012· Cement Manufacturing Process Phase 1 Raw Material Extraction Cement uses raw materials that cover calcium silicon iron and aluminum Such raw materials are limestone clay and sand Limestone is for calcium It is combined with much smaller proportions of sand and clay Sand clay fulfill the need of silicon iron and aluminum

Following is the procedure of manufacture of cement by the dry process using modern technology a Most of the cement factories are located very close to the limestone quarries The boulders upto 12 m size are transported in huge dumpers upto 300 kN capacity and dumped into the hopper of the crusher

WhatsApp)

WhatsApp)