WhatsApp)

WhatsApp)

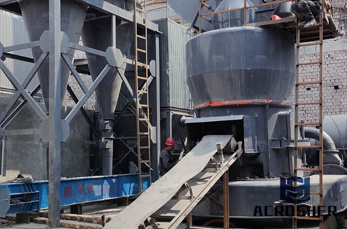

dry and wet process of cement manufacturing Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing ...

Cement the common binding material which has been used for several days on wards. There are many types of cements but portland cement is used commonly. The manufacture of Portland cement can be done by two methods 1 ...

2013/07/31· めまれている· MANUFACURE OF PORTLAND CEMENT:Raw Materials: The raw materials required for cement manufacture are. Lime stone which provides calcium. Clay which provides aluminium and is manufacture.

2017/08/12· What are the differences between the wet and dry processes of a cement manufacturer? A: Quick Answer The wet process of cement manufacturing involves adding water to finely crushed raw material, such as limestone, clay or ...

Chapter 1 Introduction to Cement Production The wet process of fine grinding is the older process, having been used in Europe prior to the manufacture of ... wet and dry process of making cement YouTube Dec 24, 2013 ... 1 The ...

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates ...

The kiln has to operate continuously in order to ensure a steady regime, and therefore uniformity of clinker. The larger existing kiln in a wet process plant produces 3600 tonnes of clinker per day. The manufacture of cement by wet ...

Chapter 1 Introduction to Cement Production Typical Manufacturing Processing Flow Chart; Newer Manufacturing Process Flow Chart ... The term cement is commonly used to refer to powdered materials which ... The wet process ...

Related Searches for wet process cement manufacturing: brazil cement companies all types of cement types of ordinary portland cement white cement price per kg extra rapid hardening cement rapid hardening portland cement cement factories in egypt ...

Do you want to show wet process cement equipment or other products of your own company? Display your Products FREE now!

dry process | cement | Dry process Cement. Contribute your ideas for this topic; Thank you for helping us expand this topic! ... The three processes of manufacture are known as the wet, ... » Learn More manufacturing ...

wet process | cement | Britannica The three processes of manufacture are known as the wet, dry, and semidry processes and are so termed when the raw materials ... cement industry UNIDO Energy conservation technique in ...

Do you want to show wet process of cement manufacturing or other products of your own company? Display your Products FREE now!

wet and dry process of cement manufacture Newer Manufacturing Process Flow . The wet or dry mix is fed into the kiln, which is one of the largest pieces of. Chat Online Manufacturing the cement kiln Understanding ...

Chapter 1 – Introduction to Cement Production The wet process of fine grinding is the older process, having been used in Europe prior to the manufacture of cement in the United States. This process is used » Learn More How ...

How Portland Cement is Made? Manufacturing Process of ..., Manufacturing Portland Cement. The basic ingredients of both the dry and wet processes are the same. By mass, lime and silica make up approximately 85% of ...

A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill); heating the rawmix to sintering temperature (up to 1450 C) in a cement kiln; grinding ...

Manufacture of Portland cement موقع الجامعة التكنولوجية على, cement wet process manufacture,Concrete Technology/ Ch1 Dr Basil Salah ٦ Comparison between wet and dry process Wet process Dry process 1 Moisture ...

In this page, you can find crusher,jaw crusher,Impact crusher,CS series cone crusher,vertical roller mill,ball mill,We company is a professional manufacture of cone crusher,stone crusher,grinding mill and also the exporter of cone ...

2017/08/20· Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process. The two processes are essentially alike except in the wet process, the raw materials are ...

...grinding the burned product, known as "clinker," together with some 5 percent of gypsum (to control the time of set of the cement). The three processes of manufacture are known as the wet, dry, and semidry processes and are so ...

2016/04/19· めまれている· wet process of cement manufacturing red xiao Loading... Unsubscribe from red xiao? Cancel Unsubscribe Working... Subscribe Subscribed Unsubscribe 24 Loading... Loading... Working...

IXMaterialsBCement5 together into a mill where the rock is ground until more than 85% of the material is less than 90µm in diameter. The wet process The clay is mixed to a paste in a washmill a tank in which the clay is ...

Feed Back Organic compounds in the cementbased Review. Organic compounds in the cementbased stabilisation/ solidification of hazardous mixed wastes—Mechanistic and process considerations Chat Online Cement ...

WhatsApp)

WhatsApp)