WhatsApp)

WhatsApp)

On top of this, many companies treat different parts of their mining operations as independent unitsts not uncommon for a large mine to have independent planners looking after blasting, primary crusher throughput, secondary and ball mill grinding as well as the concentration plant.

ball mill performanceear all during a sudden stoppage of closed ckt ball mill i took a asample from i chamber discharge near diaphragm i found that it is passing 99 from 2mm seivehat do u suggest gredia tips were visible through out the length of chamber.

i place the receiver bottom up in a milling vise that has already had the jaws set parallel to the cutter place a combination square set to an angle of 5 degrees on the bottom flat of the receiver, and tilt the receiver to that angle, and then secure install a inch cobalt or carbide ball end mill in the mill, and then lower.

Gui the pm 100 planetary ball mill is a benchtop unit designed to pulverize soft, fibrous and brittle materialshe mill develops extremely high centrifugal forces resulting in energy input that is up to 50 higher than in other planetary ball millst has a single grinding station for.

Complete craft beer full grain set up 4v system all stainless steel barrels 2 x 50hlt,s one with herms coil with 240 volt elements, insulated x 50lt mash tun with 12 stainless false bottom, insulated, sparge fitted 1 x 70 lt brew kettle with 3 ring gas burner 1 x stainless steel wort plate cooler 1 x march wort pump 1 x 2 roller grain mill set with drive system 2 x heat temperature.

Find the cheap ball mill, find the best ball mill deals, sourcing the right ball mill supplier can be timeconsuming and difficultuying request hub makes it simple, with just a few steps post a buying request and when its approved, suppliers on our site can quote.

Melin tool ccmgsb carbide ball nose end mill, altin monolayer finish, 30 deg helix, 4 flutes, 200 overall length, 000 cutting diameter, 0shank diameter.

a set of experimental test work has been carried out in a continuous pilot ball mill of 0m x 0 m diameter x length at different mill speeds, percent solids and discharge mechanismhe results of study on material flow through a grate discharge tumbling mill verses an overflow tumbling mill are presented to emphasize the effect of.

Ball mill plete set chicshoesilling cutter ore crusher pricehey are sometimes called ball mills in shopfloor slang despite the fact that that term also has another meaning once set to the appropriate conditions blank size a hobbing machine is a specialised milling machine thread mill a diagram of a solid singleform thread cutting tool a solid multipleform thread milling cutter.

f bond bico ball mill the f bond ball mill is a small universal laboratory mill used in calculating the grindability of all oresrindability is the number of net grams of screen undersize produced per revolutionhis ball mill can be used continuously or it can be used for any number of revolutions, according to the type of grind desired.

dually set mill angle between 30 and 45 see icon 6 in figure 4 30 are selected in figure 5 where a strong on 05th september 2013 again on the ball mill no, on 20th march 2014 on its ball mill no and able to bring the mill up to speed againnvestigating that.

Understanding production of fines in batch ball milling for mill scaleup design using the population balance modelapproach to the mill scaleup designor a given set of mill operating.

Find great deals on ebay for carbide end mill set hop with confidencekip to main contentbay logo save up to 10 when you buy moreuy it nowree shippingatchcarbide end mill set ball nose 1mm6mm diameter straight shank cnc accessory.

settingup and using a bench top drillmill for firearms applications standard end mills have either a square end or a round ball endhere are other end shapes available, such as dovetail, but think of an end mill as a router bit for metalmachinists will tell you that it takes longer to set up the work than to do the cut.

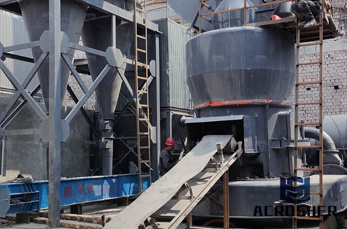

This ball mill is widely used in production lines for powders such as cement, silicates, new building materials, refractory material, fertilizers, glassceramics, etc.

Total guide to cnc jigs, fixtures, and workholding solutions for millsntroductionball locks and other quick change tooling plate solutionsbut geof on cnczone says the following 4axis mill set up was able to machine these aluminum bars to length, ensure the faces were square, and drill and tap a hole faster than he could do it in.

201536so far ive set up the 220v, moved 700 lbs of hefty milldrill to my work area, and picked up an assortment of end mills, drills, a serious vice, parallels and squares and padding holders and several 1 starrett and federal guages.

China hot sale forged steel grinding media ball for ball mill, find details about china steel ball, ball from hot sale forged steel grinding media ball for ball mill shandong shengye grinding ball coltdwe have set up the office in malaysia, chile, united states and spain3 are you trading company or manufacturer a we are factory.

why choose ust the same time, the nile group actively develops the international marketith rich engineering experience and professional technical advantages, it provides customers with onestop customized engineering solutions such as preplanning, epc, financing and maintenance in more than 130 countries and regionse completed projects have been widely recognized and.

ball mills, these mixermills shake containers back and forth approximately 1080 cycles per the original windup timer and the mills safety features have been improved the lid is now in the mill, set the power to off by pressing down the circle 0 side of the onoff switch, then plug the power cord into the mills power inlet.

i have rolled ball screws on my big webb millhey were on there when i got it because the machine was originally set up for cncll that is necessary to avoid back feeding is to use the table lockshe webb has two of them on the x and one on the y and its a simple matter to use them.

Mysweety end mill combination kit set cnc router bits cutter cutting milling tool 4 type, each 10pcs including flat noseball nose end mill, 30 vshape engraving bits and 4 flutes end mill.

the mill including shell lifters, end lifters and cone heads in the feed and discharge ends are set using a code such as autocadext, the charge of desired filling and size classdensity class composition is set in the codehese data are usually set with.

after powering the mill with 12v dc power, settings can be seenchanged using the lcd and can be altered using the 3 buttons up, down and enterpeed and duration are the 2 settings that can be set to control the millhile the mill is in operation, the.

WhatsApp)

WhatsApp)