WhatsApp)

WhatsApp)

Calculation of the power draw of dry multicompartment ball mills 6 May 2004 ... In this paper, a new approach for the calculation of the power draw of cement grinding ball mills is proposed. For this purpose, cement grinding... Read ...

Re: power consumption in cement plant Dear el, I hope i''m here to solve your query? Your calculation should be of two basis: upto clinkerisation,crushing,stacking/reclaiming,raw meal preparation,pyro and cooling should be calculated ...

Alternative Fuels in Cement Manufacturing 265 Cement production is an energyintensive proc ess consuming thermal energy of the order of GJ/tonne of clinker produced, which accounts for 30 40 percent of production costs

cement mill power calculation method ASTM International,Standards Worldwide ASTM International provides technical standards to industry worldwide. As a standards development body, the standards products offered include ...

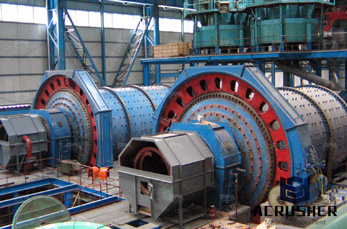

2016/08/11· Related Articles to ball mill 6 pound capacity. ball milling powders; Cement Ball Mill Power Calculation. ball mill capacity 30th for cement Used Ball Mills Capacity Cost for Cement Plant in USA. This cement ball mill is mainly ...

CEMENT INDUSTRY Output of a Seminar on Energy Conservation in Cement Industry Sponsored by United Nations Industrial Development Organization (UNIDO) and Ministry of International Trade and Industry (MITI), Japan Hosted ...

Best Practices adopted by Narmada Cement It is India''s first split location dry process cement plant with Fuller. Overview . Power Saving Calculation. ... Calculation for Mineral Phases in the Calcination of Desulfurization . Aug 18 ...

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 3 WORLD BANK GROUP • Storage of waste derived fuels in areas protected from wind and other weather elements;

2012/01/16· Reduce Energy Consumption: Cement Production How conducting manufacturing energy assessment can help identify a wide range of changes to help reduce consumption. Metering, power quality, load shedding, motor ...

Mill Power Off Calculation Mill Power Off Calculation How to calculate wind power output Small Wind Tips ... Although the calculation of wind power illustrates important features about wind ... They will use a calculation based on ...

The potential opportunities for improving energy efficiency and lower CO 2 emissions in raw material generation and production of concrete are smaller than in cement manufacturing. For instance, CO 2 emissions during transport ...

sand screw conveyor motor power calculation, Discharge Screw Conveyors calculation and design of screw conveyors, but only a few with the . tions of capacity, material velocity, torque and power consump tion of ...

2 CEMENT INDUSTRY STATISTICS 2–1 2 CEMENT INDUSTRY STATISTICS The cement manufacturing industry is identified by North American Industry Classification System (NAICS) code 32731 (formerly identified as SIC code ...

cement consumption calculation spreadsheet,Cement mining machinery customized tool for India 1, Spreadsheets for Calculating GHG emissions from Indian cement Industry Version 10 2, This customized India specific cement ...

• What is Cement? • History • Overview of the Cement Manufacturing Process • Brief Overview of Kiln Operations •Wyh Bn W?rusetsa • A hydraulic cement made by finely pulverizing the clinker produced by calcining to incipient ...

Energy Consumption Benchmark Guide: Cement Clinker Production Industry Background Cement is produced at 17 locations across Canada. The industry is concentrated in Ontario and Quebec with 10 of the 17 plants operating in ...

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates ...

cement mill power calculation method – Grinding Mill China CALCULATION OF THE POWER DRAW OF DRY MULTI–COMPARTMENT BALL MILLS. The results showed that power draw of the cement mills could . Calculated mill ...

In Nigeria, approximately 40 to 50 per cent of cement manufacturing cost is energy related; each tonne of ce ment requires 60 130 kg of fuel oil or its equivalent and about 105 kWh of electricity, depending on the cement variety and ...

Waste Heat Recovery for Power Generation Reference Documents Hebei Quzhai Cement 9000kW Waste Heat Recovery Project CDM Project Design Document Date: Sep 2007 Source: United Nations Framework Convention 2 ...

Gulin Least News turnkey for mineral processing plant design in india » The More » birla cement summer internship project » machines used in gold mining ppt » power calculation for cement manufacturing » palm kernel production ...

ROTARY AIR LOCK POWER CALCULATION DEAR EXPERTS TELL ME HOW TO CALCULATE THE DRIVE POWER OF A ROTARY AIR LOCK WITH A CAPACITY OF 400 TPH OF RAW MEAL FEEDING ? PLEASE SEND THE ...

The generation of power from a cement kiln waste gases: a case study of a plant in Kenya Stanley Ngari Irungu ... The energy costs in a cement industry account for about 26% of the total manufacturing cost of cement which is ...

ball mill calculation CGM Grinding Plant Ball Mill Calculation Horsepower calculations to rotate a ball millGrinding Calculation of power consumption for ball ... how to calculate rpm of mill in cement plant calculation ball mill Crushing ...

WhatsApp)

WhatsApp)