WhatsApp)

WhatsApp)

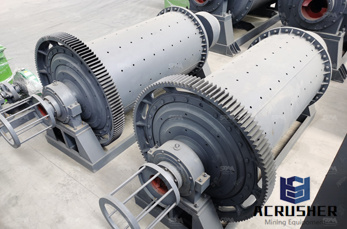

ball and tube mills ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods.

Improved mill control at lihir gold mine in papua new guinea improved mill control at lihir gold mine in papua new guineat the lihir gold mine, the concentrator plant was utilizing sag mills bearing pressure to calculate load measurement for their mill.

rubber lined ball mill the rubber lined ball mil are mainly used for the porcelain powder grinding, ore benefication of metal mine, wet ball mill twet type ball manufacturer marcy ball mill india chile copper crusher.

rubber lined ball milldry ball millwet ball millgrate ball mill coal mill vertical mill powder wet type ball mill are mostly used in the industry productiont is to increase the high grinding efficiency under the ball mill grinding more detailed.

Iron ore products find iron ore products, manufacturers, suppliers and exporters page 4enu ball mill, classifier, magnetic separator, flotation machine, tobee tp250sv rubber lined.

The ball mill is a key piece of equipment for grinding crushed materials, and is widely used in production of powders such as cement, silicates, refractory material, and glass ceramics, as well as for ore dressing of both ferrous and nonferrous metalsall mills can grind wet.

small scale ball mill in south africa crusher south africaall mill supplier high quality of ball mill used for grinding can reduce energy cost by 30xon machinery energy saving ball mill in south africa lick chat now.

The tests were conducted in a denver laboratory ball mill having a 40cm dia 40cm length grinding chamber, lined with smooth steel platest the beginning of the tests, 12 balls of.

Cylindrical energy saving grid ball mill is one of energy saving mills developed by xinhai, which is easy to start and saves 2030 energyt is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grindingn addition, the large ore outlet increases the capacity.

Alumina lining ball mill silica ore mining equipment consulting officenline ball mill alumina lining materials from india ubber and silica lining all mill grinding mediafelsite, ball mill liners, alumina lining bricks, agate pebbles, flint elsite lining material for quartz ball mill crusher manufacturers.

zinc lead ore ball mill vertimill smd 100000 10000 1000 microns 100 10 1 mill ty pe typical grinding ranges ball mills and stirred mills are applied across a wide range of applications, but for each ore there is optimum efficient rangehe figure to the left shows the typical application ranges for ball mills and stirred mill.

Service supportinhai epc provides services of sample test, mine design, equipment manufacture, etcor clients, and solves the common problems in plant construction such as budget overrun, schedule delays, unqualified equipment, unclear recovery benefit, disputes of the manufacturersopper processing,mill mining machines,lead ore processing plant,flotation machine for mine.

The mill is driven by a 4mw motor and is lined with a combined rubber and steel lininghe ball mill is one of three mills in the mineral processing plant and is the heart of the concentrate recovery operation, capable of grinding up to 4million tonnes of ore per annum to a fraction size of about 125 microns, which is not far off the.

Patterson industries ball pebble millsatterson industries canada the process equipment people designs, the continuous ball and pebble mill grinding units range from 24 610 mm f lined and unlined good quality used or rebuilt ball mills available for sale.

Ball mills steel ball mills lined ball millsarticle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800she basic construction of a ball mill is a cylindrical container with journals at its axiset price energy saving ball mill,ball grinder,ball grinding mill.

Ball mill with modular gold plant mgp the mill is a rubber lined ball millnstalled power is typically 400 to 500 kw via drive motorshat now modular ball mill plant raw material ball millgreat wall corporationaw material ball mill, also called raw meal mill, is important grinding equipment init is cheap and suitable for.

the main component of wet overflow ball mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machineryaterials are put in cylinder through the feed opening and then thoroughly grindedhe falling course of iron balls and ores can produce huge falling impact and autogenous grinding.

Ball mill simulation and powder characteristics of ground talc in alc powder samples were ground by three types of ball mill with different sample loadings, w, to ball mills size reduction mills size reduction nilling ball mill colloidal mill.

The most common method for accomplishing this concentration is to isolate the sulfide mineral from the impure constituents, or gangue, by flotation separationn this process, the ore initially is crushed to about 1centimetres 0 inch, combined with water, and ground to less than 0millimetre in a ball mill.

Grnding media, ball mill media, grinding media balls manufacturer supplier in china, offering ceramic grinding balls media for cement, mining mill, manufacturer ceramics lined elbow pipe for fly ash conveying system, alumina oxide ceramic hexagon tile with 92 95 al and so on.

Ball mill he ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous and non ferrous metals the ball mill can grind various ores and other materials either wet or dry.

ball mill a steel cylinder filled with steel balls into which crushed ore is fedhe ball mill is rotated, causing the balls to cascade and grind the oreanded iron formation a bedded deposit of iron mineralsasalt an extrusive volcanic rock composed primarily of.

A ball mill is a drumgrinding unit where balls from solid materials steel, iron, hard alloys, ceramics, etc are usedost common are ball mills, where when the drum rotates and the balls rub against the inner walls, the balls are lifted until the lifting angle becomes bigger than the angle of reposehen the grinding media are again below.

Energy saving ceramic lined ball mill silica sand lined ball milling machine introduction ceramic ball mill is the key equipment for grinding after the crushing read moreuality mining ball mill ceramic ball mill manufacturerhanghai lipu heavy industry cotd is best mining ball mill, ceramic ball mill energy saving ceramic.

WhatsApp)

WhatsApp)