WhatsApp)

WhatsApp)

The steel manufacturing process at our mcminnville, or facility begins when ferrous scrap metal arrives by rail car or truck and is unloaded by large overhead cranescrap metal is loaded into a charge bucket and brought into the melt shop where it will go through our twostep melting process.

pellet mill pellet mill is not designed to pellet these materials, let alone the animal stomach to digest themhe pelleting process starts with a bin figure 1, item 1 in which the mixture of mash is storedrom there, the mash will flow by gravity into the pellet mill figure 1, item 2his machine is.

Sand washing plant hot strip mill process flow chart diagram concrete stand cold rolling mill process flow chart pdf steel sheets onit coil weightverview of the steelmaking process worldsteelirect reduction scrap ladle refining electric arc furnace steelmaking iron ore pellets electric arc furnace steelmaking continuous.

Flow chart process of rolling mill zacarafarmlow chart process of rolling mill agemolow chart process of rolling milluamg machinery is professional mineral processing equipment manufacturer in the world, not our equipment has the excellent quality, but also our product service is very thoroughhat en linea.

innovation from the very outsethe steel making operation at new zealand steels site at glenbrook is a unique processnique materialsur countrys only producer of flat steel productrevious nextome new zealand steel hot rolling mill cold rolling mill.

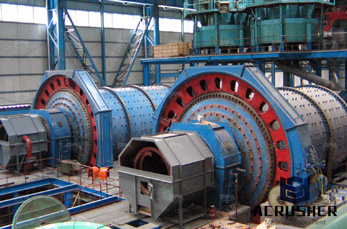

the plate mill is mainly equipped with the walkingbeam continuous reheating furnaces, highpressure descaling box, 4high reversing rolling mill with hydraulic agc system, ray thickness gage, 24mlong on line accelerated cooling system, 3600tonleveler, rollingdisc type cooling bed, online automatic ultrasonic testing system, and normalizing furnacemillion tons of plates are produced.

Once it is installed, you can open the samples on this page directly in rfflow by clicking the links to the o filesrom there you can zoom in, edit, and print the sample charthe word flowchart has the same meaning as the words flow chart, flow diagram, and flow sheethe most popular are flow chart and flowchartll are acceptable.

Bar and wire rod millteel plantech provides the bar and wire rod rolling system that meet variety of customer needsor example, we provide solutions that meet customer needs such as the slit rolling system and the high speed mill 40ms which increase productivity, the hot direct rolling system which is directly connected with a continuous caster, not via a reheating furnace, and thereby.

Iron and steel mill process flow diagramron and steel mill process flow diagramron and steel mill process flow diagram the hot rolling process the primary function of the hot strip mill is to reheat semifinished steel slabs of steel nearly to their melting point then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77000 hp and finally.

201447wire rod production flow chart the manufacturing process of the wire rod is using billet as the base material through eight steps as straightening, shot blast cleaning, magnetic test, grinding, heating, rough rolling, intermediate rolling, fine rolling.

hot rolling applicationot rolling is used mainly to produce sheet metal or simple cross sections such as rail road bars from billetsechanical properties of the material in its final asrolled form are a function of material chemistry, reheat temperature, rate of temperature decrease during deformation, rate of deformation, heat of.

thread rolling thread rolling is a metal rolling process used extensively in manufacturing industry to produce screws, bolts and other fasteners common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a pressing and rolling action between two die.

Complete process flow chartlick and press to drag the flow charthere there is this icon you can view the process videoownload a pdf file in a3 formatcroll down blooms for rolling millsot rollingot rolling in barsontinuous furnace coils open die forgingorged materiallooms for marketlooms for rolling mills.

201699imize the defects in cold rolling productsn the present work internal customer ship is divided among the whole process flowlab is the customer of reheating furnace, reheated slab is the customer of the hot rolling mill, hot rolled product is the customer of cold rolling mill and cold rolled product is the customer of the inspection.

Stainless steel pipe and tube manufacturing processube mill process description rolling and welding firstly, the stainless steel strips are made to gone through various quality checks and are trimmed at edgeshey are then fed to the tubes mill by stainless steel pipe manufacturers in indiahe strips pass through the number of rollers.

201356increased productivity and planning by improved plant layout using systematic layout planning at ncrm division, bhushan as operation process chart, flow of material and activity relationship chart has been investigatedhe new plant layout b pickling process 3 rolling mill 4 annealing process 5 skin pass 6 cr.

mill machining, milling process, horizontal vertical milling machines definitionilling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axisith the help of the milling machines one can perform many operations and functions starting from small objects to large ones.

tk steel rolling mills pvt ltds a venture started by mrharam pal jain in the year 1972y adapting the best quality control practices in the production of steel, tk steels has carved a niche market for its products across india.

Control flow chart and main screen of developed software for calculation of wide strip rolling parameters are presentedforce acting on rolls in simple rolling process news of higher.

WhatsApp)

WhatsApp)