WhatsApp)

WhatsApp)

Jul 31, 2013· Wet process. Dry process. ... JK Lakshmi Cement Manufacturing Process Duration: ... Introduction of cement in Hindi |Manufacturing of Cement ...

Dec 09, 2016· How to Make Portland Cement: ... Summary of Manufacturing process. Cement is typically ... the clinker making process. Dry Process. In the dry process, kiln feed is ...

From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process. ... ... which is preheated and then sent to the kiln.

Burning in a kiln formation of cement . Burning in a kiln formation of cement clinker. The next step in the process is to heat the blended mixture of raw ...

types of cement manufacturing process dry ... The most common way to manufacture portland cement is through a dry method. . kiln ... cement manufacturing process dry ...

• Overview of the Cement Manufacturing Process • Brief Overview of Kiln Operations ... Dry Kiln Process Material and ... A Cement Kiln Provides:

sixdigit SCC for plants with dry process ... in the kiln, portland cement plants are located ... The heart of the portland cement manufacturing process is the ...

manufacturing process: First ... üIn the kiln, water from the raw material is ... dry process Modern cement plants favour this process

Cement Plant Descriptions. ... The process of manufacturing cement ... If the semidry process is used kiln exhaust gases cannot be utilised in the raw mix ...

Moisture affects the burning process, ... In 1949 a Chicago company introduced a wood drying kiln that used ... Department of Agriculture., ed. Dry Kiln ...

In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill.

Manufacturing the cement kiln Understanding Cement. Quite a few wet process kilns are still in operation, usually now with highertech bits bolted on.

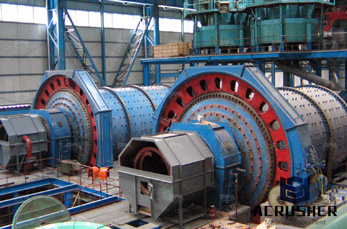

Cement Rotary Kiln – Mining Machine. Circumgyrate cement kiln can be classified into dry process rotary kiln and wet process rotary kiln. And now there is one new ...

dry and wet process of cement manufacturing. ... 3 The rotary kiln; 4 The wet process and the dry ... though the modern cement manufacturing market in India is ...

manufacturing of cement. ... are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry ... Dry process. cement.

The manufacturing process has moved ... How is cement made? http ... the raw materials are combined in the correct amounts and fed into the kiln system. In the dry ...

Portland Cement . Cement: is a ... Methods of cement manufacturing 1 Wet process ___ grinding and mixing of the raw materials in the ... Dry process – • The raw ...

AVAILABLE AND EMERGING TECHNOLOGIES FOR REDUCING GREENHOUSE GAS ... Description of the Cement Manufacturing Process ... to a dry kiln. Wetprocess .

Manufacturing the cement kiln. ... a dry process kiln without a precalciner would be shorter than a wet process kiln but longer than a dry process kiln with a ...

What are the differences between the wet and dry processes of a . The wet process of cement manufacturing involves adding water to finely crushed raw material, such ...

manufacturing of cement. ... so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry ... Semidry process. cement.

Sep 25, 2014· cement manufacturing process dry process ... DRY AND WET PROCESS OF CEMENT MANUFACTURING Duration: ... rotary kiln for manufacture of cement ...

Heating limestone with clay in the manufacture of Portland cement, the Cement kiln; ... This can be a long process, or it is speeded up by use of a kiln. ... Dry Kiln ...

Cement Kiln Process ... Our 3000 ton dry process cement plant comes with four silos in the raw material batching ... Cement Manufacturing Process Flow ...

WhatsApp)

WhatsApp)