WhatsApp)

WhatsApp)

variation is between – % which is lower than mill ball filling percentage, according to the designed ... or investigation on the ball filling ratio

Nov 10, 2012· SATAREM. Characteristics of SAT ball mill . • A special L/D ratio, much smaller than a traditional mill • Single compartment design without a diaphragm

ball mill filling calculation – 10 Dec 2013 . calculation of filling volume in ball mill — SBM Machine calculation of . calculation in filling ratio for ball ...

ATTRITORS AND BALL MILLS HOW THEY WORK . A typical ball mill has an L/D ratio of :1. Ball mills are filled with spheres or other shapes ... Ball mills can blend ...

The efficiency of the early stages of grinding in a ball mill is much ... used in ball mills.... EF2 Open Circuit (ball mill only) 1 ... when the L/D ratio ...

Grinding mills, Ball Mill, Vertical Roller Mill for How to find t/d ratio for tube mill. ... Ball mills have a length to diameter ratio in the range

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on ...

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... Figure Effect of mill filling on power draft for ball mills. ... L = belly length. Dm = mill diameter.

Optimum choice of the makeup ball sizes for maximum throughput in tumbling ball ... ball size in the mill, and d min is the ... mm/ mm ball mix ratio ...

Low Rpm Tungsten Powder Ball Milling; ... Ball Mill 1/2 ... tungsten carbide ... A typical ball mill has an L/D ratio of :1. Ball mills are filled with ... Read more.

Maximum utility of the ball energy, • The relatively smaller L/D ratio Get Price. Ball Mill Forum Just 4 % of the energy from ball mill is used for comminution. ...

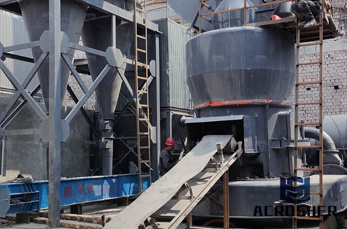

Xinhai is the leading supplier of mining machine and equipment at home and abroad, providing many complete sets mineral dressing equipment such as bal

Cement Ball Mill Sizing Explanation. The Cement Grinding Office. The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy;

FLSmidth ball mill for cement grinding. Versatile system based on standard modules 2 The FLSmidth ball mill is designed for grinding of clinker, gypsum and dry or

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time on ...

Ball mills designed for long life and minimum maintenance Metso overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to ... When the L/D ratio is 2 to 1 ...

ball mill kw calculator ... 46 x 165 m L/D ratio Mill drive 358 5000 kW Diaphragm Double blind plate Mill ... required to turn a ball mill is approximated by: P ...

How to Size a Ball Mill Design Calculator Formula. ... Ball milling – a ball mill with a diameter of meters, inside new liners, grinding wet in open circuit.

2. State of the artL/D ratio and ball charge filling ratio The L/D ratio of the ball mill was varied in four steps of,, and, and the ball charge ...

Optimization of ball mills in combined grinding systems with particular regard to the L/D ratio on ResearchGate, the professional network for scientists.

A typical ball mill has an L/D ratio of ... silica or rubber. Ball sizes range is size from 6" diameter, drawing less than 1 hp (.75 kW), to 1618 feet diameter, ...

Jan 25, 2016· Video embedded· Grinding mill filling ... with over 30 calculation of the ball mill reduction ratio Home Mining Mill calculation in filling ratio for ...

A typical ball mill has an L/D ratio of :1. Ball mills are filled with spheres or other shapes made of steel or ceramics; or with

WhatsApp)

WhatsApp)