WhatsApp)

WhatsApp)

Mill liners fill a basic role to protect your mills from the intense wear and tear that comes from grinding down hard raw materials But even if they all do the same job not all mill liners are created equal From the abrasion resistance of rubber to the impact resistance of steel

End and shell liner design in these mills is much the same as for SAG mills The effect of liner design on performance is equally as important For instance in an iron ore operation using 64 m 21 ft mills mill throughput was increased by 15 percent and power consumption reduced by 13 percent by liner

installation of liners for ball mill and sag millFelona installation of liners for ball mill and sag millMill SHELL Liner HEAD Liners Grate discharge heads for ball mills are completely assembled in the shop with grates clamp bars pan liners and center discharge liners in place Depending upon available handling facilities the head or shell can be lined separately in a repair bay or after

Rely on our proven track record of SAG and AG Mill superiority Since the early 1980s we have been designing and manufacturing SemiAutogenous SAG and Autogenous AG Grinding Mills under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in the range of 615 while autogenous grinding uses ore only

Mill liners developed by Multotec include Ball Mill Liners SAG Mill Liners AG Mill Liners as well as Scrubber Liners Focusing on good fitment of liners in which Multotec are experts results in reduced installation downtime which in turn facilitates increased production

Simultaneous reline of SAG and ball mills completed with Outotec Installing a new shell lifter on the SAG mill using the reline machine than 73 hours to complete Skilled isolations set up on the mill and installation of the

Ball Mill Liners Mill Liners Cement Mill Liners Steel Mill Liners White Iron Castings Wearresistant Castings Ni Hard Liners Crusher Wear Parts Alloy Steel Castings Heat Resistant Castings Grinding Media Sag Mill Liners Ball Mill Lining Grinding Mill Liners Mill Lining System Mill Liner Design and Installation

History is that mill liners have evolved over time Liner design has a significant effect on mill performance and liner life Engineering approaches have highlighted mill performance with mill modelling and the use of improved materials Liner design with the advent of large diameter SAG mills the issues of

In the case of the large SAG mill referred to in Fig 1 the mill''s initial volume is 757m3 when new liners are installed with the volume on average increasing to 792 m3 at the end of shell liner life over three liner lives for the 2010 calendar year which equates to an average increase of 44

Mechanical installation of a 28 x 155 SAG mill including lubrication and cooling system mill wear liner as well as commissioning assistance and surveying after trail run

VALBY PulpMax Mill Liners are highperformance lightweight mill liners uniquely constructed with a rubberceramic matrix and reinforced with carefully selected highhardness steel inserts They are customisable to fit the specifications of any SAG or ball mill

Mines WA 36ft SAG mill the number of Outer Head Liners was reduced from 36 to 18 pieces and in doing so reduced the time to replace them by 9 hours at a cost downtime saving of about U25000 per hour In this case the liners sections are 35 t each For smaller mills the liners have to be handled and installed manually so smaller blocks with

Our AGSAG mill liners are manufactured to the highest industry standard for Autogenous GrindingAG SemiAutogenous GrindingSAG Primary Secondary and regrind rod or ball mills MGS Casting mill lining system designed by our highly trained and dedicated team throughout the world has taken your entire comminution circuit into consideration

In many grinding plants mills which have metallic or rubber liners suffer from bolt breakage Our technicians come across broken mill bolts at many sites around the world to the operators of the mills it is an almost normal occurrence but if you have breaking bolts there is an underlying problem which needs to be fixed

With Metso''s unique attachment system liner bolts are inserted and removed from the outside of the mill So there is no need for any member of the installation crew to be in the dangerzone of the liners while inserting or removing liner bolts The liner handler operator can simply position the liners acting alone

We are the world leader in designing and supplying highly engineered grinding mill liners for SAG AG ball and rod milling GENERAL DESCRIPTION Our innovative liner designs and proven alloys maximize mill performance and availability while minimizing costly down time

Multotec''s expert ball mill lining installation and fitment is based on over 45 years of experience Multotec ball mill liners are customised to your application using stateoftheart softwaredriven designs This means that your ball mill lining solution precisely fits into your application

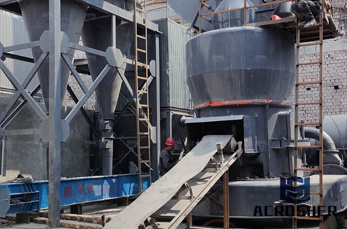

Installation Of Liners For Ball Mill And Sag Mill We are a largescale manufacturer specializing in producing various mining machines including different processing equipment and building materials equipment And they are mainly used to crush coarse asphalt gravel concrete etc

Metso has experience of over 8000 grinding mills globally including manufacturing and delivering the largest SAGAG mills in the world Our experts welcome the opportunity to assist you with circuit and circuit control design as well as startup operation and optimization of your mill

WhatsApp)

WhatsApp)