WhatsApp)

WhatsApp)

Industrial development has lead to higher energy consumption, and emission of greenhouse gases. Cement industry plays an important role in energy .

Rotary kiln, in addition to calcine cement clinker, is also used to calcine clay, limestone and the slag drying, etc. In the refractory materials production, using ...

Energy Saving Rotary Kiln, ... New Design and Energy Saving Cement Kiln/Cement Machiner/Cement Rotary Kiln. US / Set . 1 Set (Min. Order)

Official FullText Paper (PDF): Energy Savings Measures for Clinker Production in Cement Industry

Energy optimization in cement manufacturing ... Fans are predestined for saving en ... atures, kiln energy requirements,

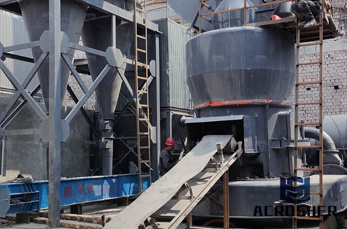

energy saving in cement kiln. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size ...

Kiln Shell Heat Loss Reduction. ... This ENERGY STAR guide provides current real world examples of cement plants saving energy and reducing cost and carbon dioxide ...

In this paper, energy saving measures in the cement industry, ... E BirchEnergy savings in cement kiln systems energy efficiency in the cement industry.

How does cement production become energy efficient and environmentally ... There is enormous potential for saving money in the cement industry. ... in a rotary kiln.

Iranian Fuel Conservation Company (IFCO) along with the Power Ministry in Iran has set energy consumption standards for different industries. For the cement industry ...

Energy Consumption Benchmark Guide: Cement Clinker Production 0 1 ... energyefficient dry kiln ... Energy Consumption Benchmark Guide: Cement Clinker Production. 10

cyclone preheater system and a rotary kiln. b. The grinding process, where clinker along with ... Share of type of Energy in cement production

Lime rotary kiln is active lime kiln which is the heat treatment equipment for bulk or slurry materials, the machine is widely used in construction cement materials ...

China Energy Saving Active Lime Rotary Kiln Manufacturer, Find details about China Active Lime Rotary ... Energy Saving Cement Production Plant Equipment and so ...

China (Mainland) | Manufacturer, Trading Company. Supplier Assessments: Response Time: 24h48h: Response Rate: %

The cement industry accounts for approximately 5 percent of current anthropogenic carbon dioxide (CO 2)emissions worldwide. World cement demand and production are ...

The knowhow on modern energy saving and ... heat from the kiln in the ... for the Use of Energy Saving Technologies in the Ceramic and Cement Industries in ...

When it comes to achieving the best energy consumption, ... are added, the evaluation of the benefits of energy saving investment can become ... Cement Kiln Process ...

ii Energy Efficiency Improvement and Cost Saving Opportunities for Cement Making An ENERGY STAR® Guide for Energy and Plant Managers Ernst Worrell, University of .

Energy Saving Measures in Cement Industry ... mixed, and fed into the kiln in the form of a slurry. ... Energy saving possibilities in pyroprocessing

China Energy Saving Lime Rotary Kiln for Active Lime Production, Find details about China Lime Rotary Kiln, Rotary Calcination Kiln from Energy Saving Lime Rotary ...

The tightness of cement Kiln is better, so energysaving effect is good, especially for hightemperature fans. Calculating the energysaving of fans according to data ...

Cement Rotary Kiln The cement rotary kiln (cementrotarykiln) is mainly used for cement clinker, cement kiln dry process production of cement kiln .

LBNL54036Revision Energy Efficiency Improvement ERNEST ORLANDO LAWRENCE BERKELEY NATIONAL LABORATORY and Cost Saving Opportunities for .

WhatsApp)

WhatsApp)